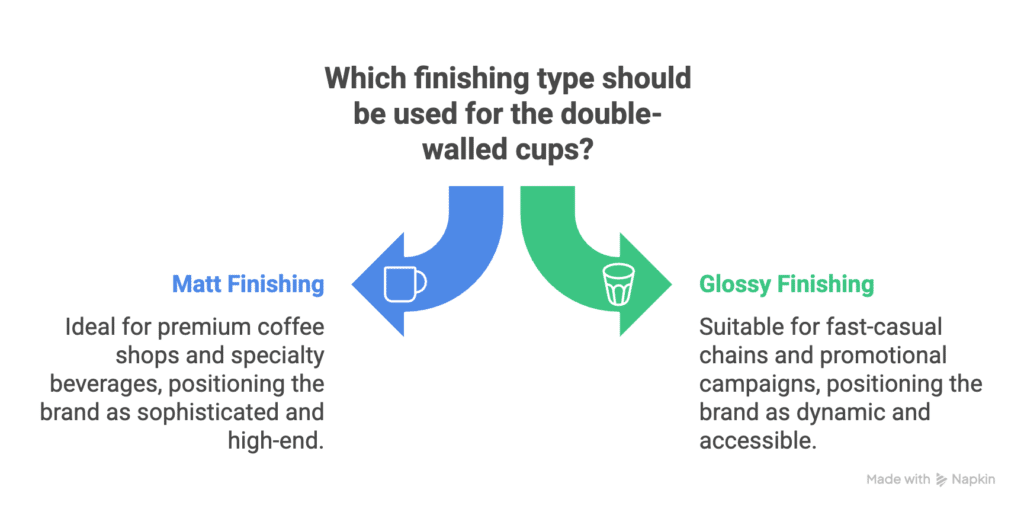

When customizing double wall paper cups, one of the most common questions procurement buyers ask is: Should I choose a matt or glossy finish?

This single decision affects your brand perception, cost structure, and even consumer touch experience. But how do you know which one is right for your coffee chain or eco-packaging line?

Matt and glossy finishes on double wall paper cups each offer distinct advantages. Matt finishes, created through UV offset printing, offer a premium, textured look ideal for luxury brands, while glossy finishes—produced by adding varnish—provide a vibrant, smooth surface suited to photographic or complex graphics. Functionally, both finishes offer comparable insulation and environmental impact. However, matt finishes tend to cost more and provide slightly better heat retention (up to 5°C) under testing conditions by Get Bio Pak Co., Ltd. (source: Onlinelibrary)

Understanding Double Wall Cup Construction

To understand how matt or glossy finishes impact your product, you must first understand where the finishing is applied.

Double-layer paper cups consist of two components:

- Inside layer cup: Holds the beverage and provides primary insulation: 1 side PE coated paperboard

- Outer wrap layer: A separate layer wrapped around the cup that enhances branding and additional insulation: 1 side PE coated paperboard or white cardboard

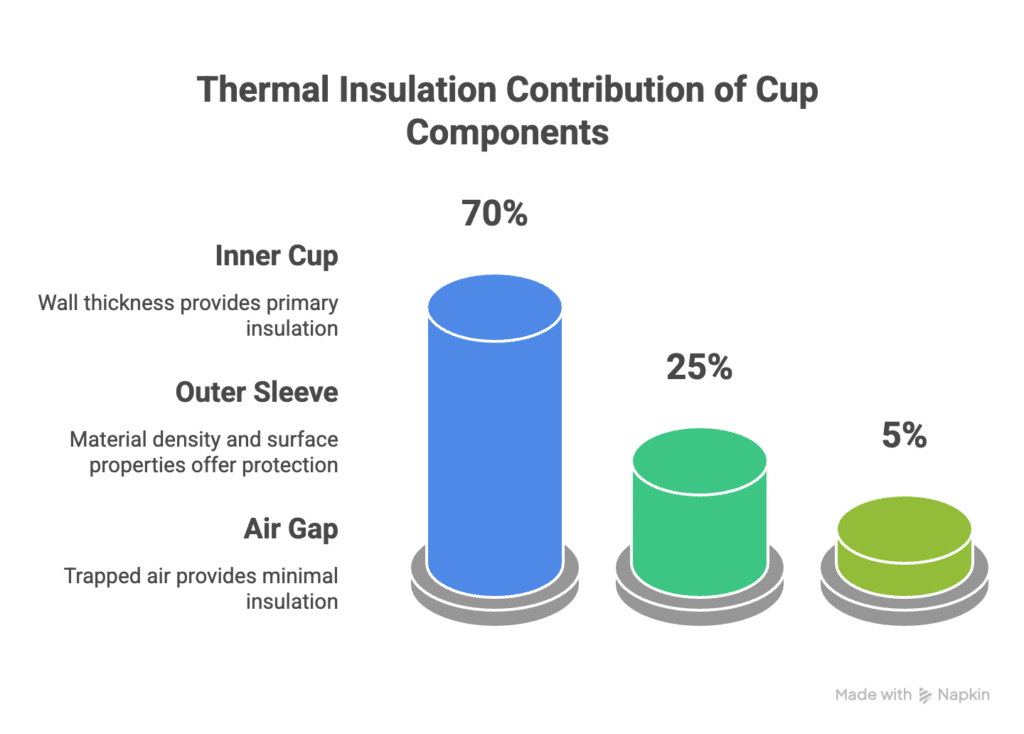

The thermal performance of double-walled cups depends on three critical structural components. The inner cup contributes 70% of the insulation capacity through its wall thickness. The outer sleeve provides 25% of thermal protection through material density and surface properties. The air gap between these layers accounts for the remaining 5% through trapped air insulation.

The finish only applies to the outer wrap. It does not influence the liquid contact surface, safety, or the material’s food compliance.

Material Basics: The Foundation of the Finish

Most manufacturers utilize two primary materials for the outer sleeve construction.

White cardboard represents 70% of market applications due to cost efficiency and reliable performance. Single-side PE-coated paper comprises 30% of premium applications, commanding a 23.40% price premium over standard cardboard options.

| Material Type | Market Usage (%) | Key Attributes |

|---|---|---|

| White Virgin Cardboard | ~70% | No PE coating, recyclable |

| Single PE-Coated Paper | ~30% | Moisture-resistant, higher cost (23%) |

Printing is typically done using offset printing (including UV printing), which produces higher color accuracy and depth compared to flexographic printing.

UV offset printing is used for matt finishes, while glossy finishes require an additional varnish coating step.

What Makes It Matt or Glossy?

Offset Printing Foundation

Double wall cup manufacturing relies on offset printing technology for superior color reproduction and dimensional quality. Offset printing delivers enhanced vibrancy compared to flexographic alternatives, enabling complex photographic content and detailed brand graphics.

The printing process creates the foundation for both matt and glossy finishing applications. Color density and ink adhesion properties vary significantly between finishing types, requiring specific ink formulations and curing processes.

Matt Finishing Production Process

Matt finishing requires UV offset printing application with specialized curing protocols. The UV process ensures heat resistance at 180°C manufacturing temperatures, preventing pattern degradation during cup formation.

The textured surface emerges from controlled ink absorption and curing rates. This texture creates microscopic air pockets that enhance thermal resistance while providing distinctive tactile properties. Our custom paper cups printing service utilizes advanced UV technology to achieve consistent matt surface quality.

Glossy Finishing Production Process

Glossy finishing combines standard offset printing with protective varnish coating application. The varnish layer provides pattern protection while creating smooth, reflective surface properties.

The coating process requires precise application timing and thickness control. Excessive coating creates handling difficulties, while insufficient coverage compromises durability and aesthetic appeal.

| Finish Type | Printing Method | Surface Effect | Best For |

|---|---|---|---|

| Matt | UV Offset Printing | Non-reflective, textured | Premium brands, minimalist designs |

| Glossy | Offset + Varnish Coating | Reflective, smooth, vibrant | Detailed images, colorful brand visuals |

Matt finishes absorb more light, creating a calm, subtle feel. Glossy finishes reflect more light, making graphics pop.

Decision Criteria: Matt vs Glossy by Function

Visual Appeal and Brand Positioning

Surface finishing directly influences brand perception and customer experience. Glossy finishing enhances photographic printing content through light reflection and color saturation. Complex imagery and detailed graphics achieve maximum visual impact with glossy applications.

Matt finishing communicates premium positioning through sophisticated, understated elegance. The non-reflective surface maintains consistent brand visibility across varying lighting conditions, supporting upscale coffee service environments.

Customer Experience

Tactile properties significantly impact customer perception and handling comfort. Glossy surfaces provide smooth, sleek sensations that feel refined and polished. The coating creates effortless grip transitions and comfortable handling characteristics.

Matt surfaces deliver textured, substantial feel with enhanced grip security. The rougher texture provides superior handling control, particularly beneficial for hot beverage service and busy environments.

1. Brand Aesthetics

Glossy finishes are energetic and eye-catching. Matt finishes feel refined and calm. The choice should reflect your brand’s personality.

2. Touch and Feel

- Glossy: Silky and smooth.

- Matt: Textured and grippy.

3. Insulation Performance

Test results at Get Bio Pak Co., Ltd demonstrate:

Temperature retention testing reveals matt finishing superiority in thermal performance. Under controlled laboratory conditions using 95°C coffee service temperature, matt finished cups maintain 5°C higher external surface temperatures compared to glossy alternatives.

The performance difference results from surface texture impact on thermal conductivity. Matt surfaces create additional air pocket insulation while glossy coatings conduct heat more efficiently through smooth surface contact.

| Test Parameter | Matt Finishing | Glossy Finishing | Performance Difference |

|---|---|---|---|

| External Surface Temperature (°C) | 42°C | 47°C | -5°C (Matt advantage) |

| Heat Retention Time (minutes) | 18 minutes | 15 minutes | +3 minutes |

| Customer Comfort Rating | 8.7/10 | 7.2/10 | +1.5 points |

| Feature | Matt Finish | Glossy Finish |

|---|---|---|

| Temperature drop after 10 min | 5°C lower | Baseline |

| Grip Comfort | Better friction | Smoother feel |

Our testing methodology follows international thermal packaging standards, ensuring reliable performance data for procurement decisions. The 5°C temperature difference represents substantial improvement in customer handling comfort and beverage temperature maintenance.

Our laboratory testing follows International Organization for Standardization thermal packaging protocols. Temperature measurements utilize calibrated infrared thermography equipment with ±0.1°C accuracy standards.

Test conditions replicate actual service environments with 95°C beverage temperatures and controlled ambient conditions. Multiple sample testing ensures statistical significance and reproducible results.

Quality assurance protocols verify consistent performance across production batches. Every manufacturing run undergoes thermal testing to maintain performance standards.

This variance stems from airflow and texture but does not affect core insulation factors like inner wall thickness or air gap.

4. Cost Consideration

- Glossy cups: More economical due to simpler process.

- Matt cups: Slightly higher cost due to UV coating.

5. Sustainability

When made with white virgin card, are equally recyclable and compostable.

Both finishing types maintain equivalent environmental credentials through identical base material composition. Matt and glossy finishes achieve equal recyclability ratings and sustainability certifications. The UV printing process for matt finishing utilizes environmentally compliant inks and curing systems.

Our sustainability commitment ensures both finishing options meet international environmental standards without compromising performance or aesthetics.

How to Choose: Final Recommendations

Think in terms of your customer’s touch, your brand’s tone, and your budget. If you’re launching a bold, colorful design, glossy might better showcase it. If you’re building a boutique or luxury vibe, matt is the better visual match.

Matt finishing commands premium pricing compared to glossy alternatives due to specialized UV printing requirements and extended processing time. The price differential typically ranges from 8-15% depending on order volume and customization complexity.

Volume-based pricing structures favor matt finishing for high-volume operations. The thermal performance benefits justify premium pricing through reduced customer complaints and enhanced brand perception.

Return on investment calculations demonstrate positive outcomes for premium coffee service operations. Customer retention improvements and reduced handling incidents offset initial cost increases within six months of implementation.

Don’t choose based on assumption. Ask your supplier for samples, test the finish under real conditions, and align with your target customer expectations.

Still deciding? Our specialists are ready to help. Contact us for expert finishing advice and sampling.

Company Highlight: Why Work with Get Bio Pak

At Get Bio Pak Co., Ltd, we specialize in customized double wall coffee paper cups. We offer:

- Over 12 years of manufacturing experience

- Expert UV offset and varnish printing

- Custom finishing for both matt and glossy cups

- FSC, BRC, HACCP, ISO22000 certified production lines

Explore our double wall paper cups and custom paper cups printing for more details.

For service, compliance, and logistics info, visit our service page or quality assurance.

FAQ Section

Q1: Is matt or glossy better for takeaway branding?

Matt adds elegance and upscale texture; glossy delivers visual pop. Choose based on your brand tone.

Q2: Will glossy paper cups feel slippery?

Glossy cups feel smoother, but they maintain grip due to structural rigidity. Most brands find them customer-friendly.

Q3: Are both finishes suitable for high-heat drinks?

Yes. Both matt and glossy cups are designed to withstand coffee temperatures (under 95°C).

Q4: Which finish costs more?

Matt costs more due to UV printing and higher paper spec usage. Glossy is more cost-efficient.

Q5: Can both finishes be composted?

Yes. Both can be made from FSC-certified boards and are suitable for composting if no PE coating is applied.

Q6: Which is better for double wall paper cups: matt or glossy?

A: Matt is better for upscale, premium feel; glossy suits bold, colorful designs. Both offer similar insulation and recyclability.

Q7: Does finishing affect cup insulation?

A: No. The finish only affects the surface layer. True insulation comes from cup thickness and air gaps.

Learn more from our Paper Cup Guides and Tips or see who we compete with at Top 6 Paper Cup Companies in China.