The paper cup market has seen significant growth in recent years due to the increasing demand for convenient and disposable products. Paper cups are commonly used for hot and cold beverages, as well as for serving food items such as ice cream and yogurt.

One of the key materials used in the production of paper cups is High Bulky PE Coated Paper. This type of paper has an extra layer of coating that helps it achieve certain qualities such as extra gloss, durability, tear resistance or smoothness.

High Bulky PE Coated Paper (high bulk paper, high volume paper, volume paper), the term “bulky” refers to a wood pulp paper with a bulk rating exceeding average values for the present paper glass. For example, the average bulkiness of paper is between 1.0 and 1.3 cm3/g, while the paper with bulkiness of 1.4 or higher can be considered as high bulk paper.

High Bulky PE Coated Paper is a popular choice for paper cup manufacturers due to its ability to provide a strong and durable product while also being cost-effective. The use of this material allows for the production of paper cups that are able to withstand hot liquids and maintain their shape without leaking or becoming soggy.

1. What is bulkiness

Bulkiness is a parameter (ratio) connecting the paper density (g/m2 or GSM) and its thickness (um). The greater the thickness of the paper sheet, the bulkier it is.

Bulk sheet thickness (um) = bulkiness (cm3/g) * density (g/m2)

For example, paper density comprising 170 g/m2 and bulkiness comprising 1.6 cm3/g the paper sheet thickness will be 272 um (microns)

Some famous paper brand(APP brand paper ) high bulk technical date sheet:

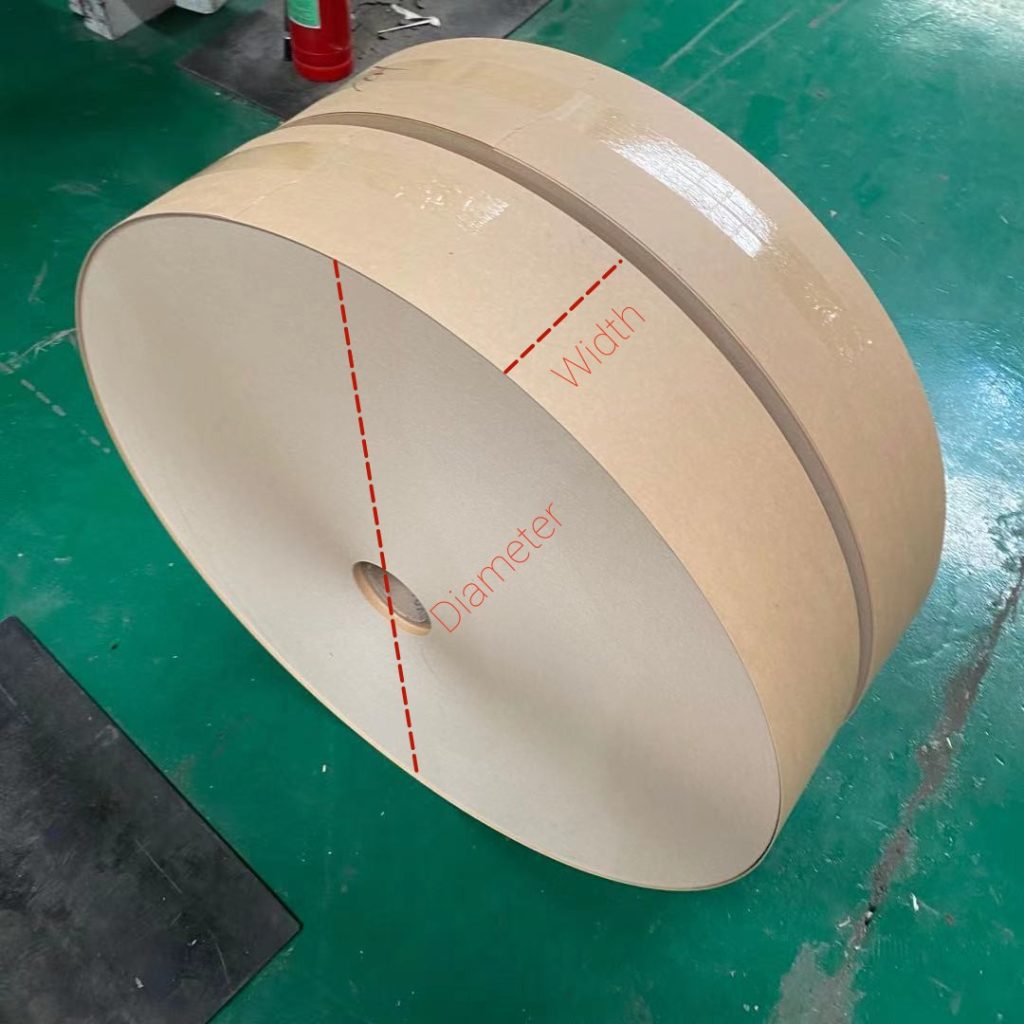

2. The cross view of paper sheet

3. Economic yield of bulk paper, % (yield, yield effect)

The possibility of medium bulk paper’s changeover to paper with high bulkiness is usually available. In this case the high bulk paper’s density is less than the density of substituted paper. Meanwhile the metric parameters of the reel remain almost unchanged.

The yield through the change of paper to the one with lower density comprises:

(Paper density (g/m2) – Density of the bulk paper (g/m2)) / Paper density (g/m2)

Assuming keeping same thickness paper cup fan, when the normal bulk paper (density of 190 g/m2) is replaced with bulky paper (density of 170 g/m2) the yield is 10.5%. This means one should buy 10.3% less paper as measured by weight for the same planned number of paper cup fans, or means you may have 10.3% more quantity of paper cup fans than normal bulk paper.

4. High Bulky paper effects on paper cup forming machine

High Bulky paper will not affect the paper cup forming process according to existing paper cup machine technology(no matter heater or ultrasonic), you can check details with your paper cup machine supplier.

5. Advantages of high bulky paper

A. Low down cost – low each cup raw material costs and transportation costs due to lighter weight

B. Better thickness and paper stiffness

C. Higher resistance level to breakage or leakage(Paper Cup), folding resistance (Food box)

D. Good color rendering, saving on ink and varnish(Flexo printing or offset printing)

If this post helps you better understand the raw material of paper cups, you can share it with your relations if necessary.