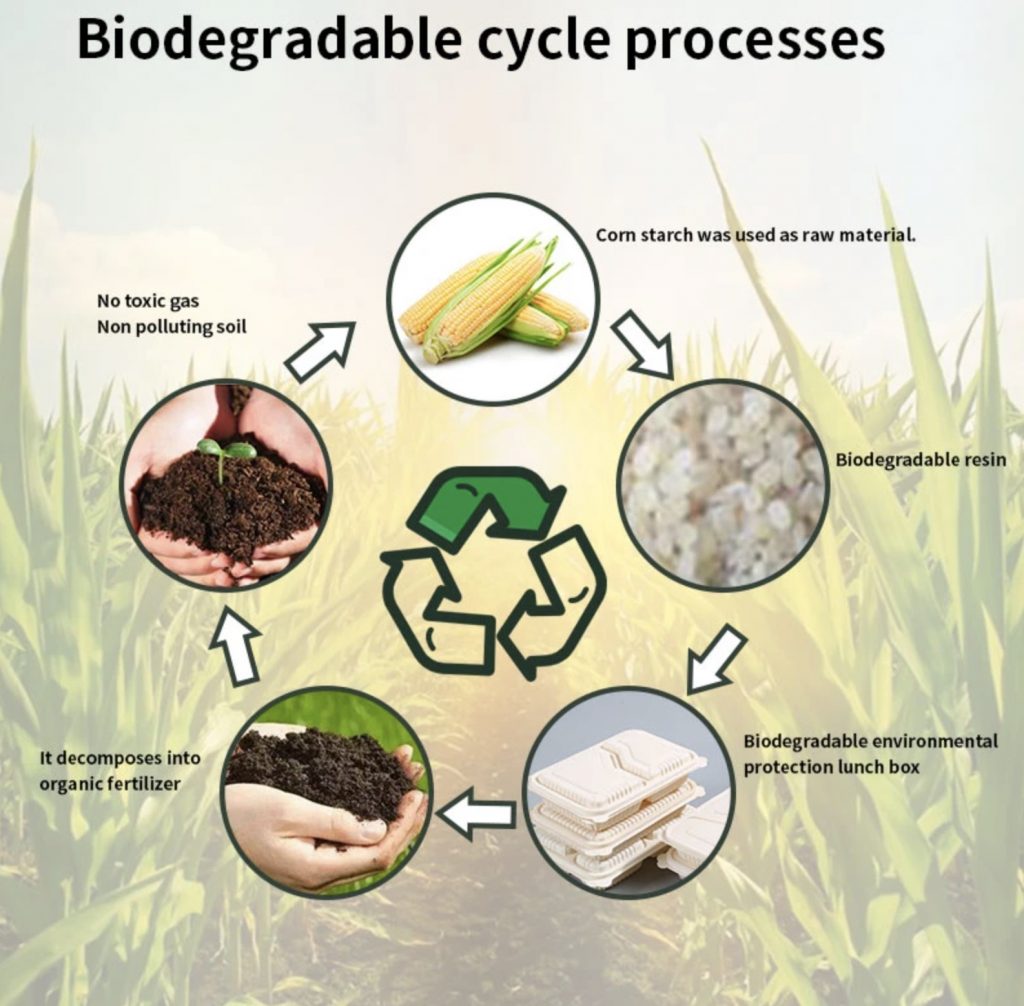

In fast food restaurants and even during travel, biodegradable disposable tableware can be used in place of regular plastic tableware. Biodegradable disposable tableware does not generate waste or garbage, it is very green and environmentally friendly. As more countries commit to environmental protection, this biodegradable disposable tableware made of biodegradable biological waste such as bagasse, grain bran, corn, and corn is gaining popularity, the raw material of tableware makes its biodegradable or not, the disposable tableware developed by potato, rice starch and tapioca starch, is it be a choice for a new market ? Today we talk about corn starch-based tableware.

- What is corn starch tableware?

- Why is corn starch tableware?

- How is Corn Starch Plastic Made?

- Features of Corn Starch tableware

- SPI Logo of the Corn Starch tableware

- Advantages of Corn Starch Tableware

- What Should You Look for When Purchasing Corn Starch Tableware?

- Questions and Answers About Corn Starch Tableware

What is corn starch tableware?

Corn starch tableware is blow molding made of corn maize starch or waste starch environmentally-considerate raw material tableware, derived from the corn kernel, it consists of most corn starch, non-toxic, 100% natural and biodegradable, a sustainable and renewable resource, available in a wide range of serving tray, plate, cups, cutlery, multi-comparts containers, clamshells box, round bowls and rectangle containers.

Why is corn starch tableware?

Among all starches, “Corn” is a good source of plant residues. It has many advantages, including high starch levels, excellent consistency, biodegradability, and widespread availability. Corn is also known as the most widely available agricultural cereal in the world. There are six varieties of corn. Flour, dent, flint, pop, pod, and sweet corn are the different types. Because of environmental effects, the properties of all types vary significantly. Corn production was nearly 6 billion tons in 2022, accounting for 34% of global cereal production. With this figure, corn becomes the world’s third-largest food grain.

Corn has a short root and a few stems. Parts of the plant are discarded after harvesting. Corn is the most common source of starch. In food manufacturing, alpha-related glucose is used as a slippery, water-retaining, and bulking agent. The majority of corn starch kernel is starch with traces of sugar, protein, oil, and ash. Corn can be used to extract natural fibers such as stems, straw, and leaves. Corn fibers have different properties than other agricultural bio-products, such as 90% storage and greater availability than other natural fibers.

We can say corn-starch is a semi-crystalline biopolymer. It’s made up of a mix of linear amylose polysaccharide and unitary amylopectin. Numerous studies using thermoplastic corn starch to develop biopolymer films with plasticizing agents have been conducted. A study, for example, looked into the production of plastic film using corn starch and urea plasticizer. According to the findings of this study, the mechanical properties of starch biopolymers improve as the urea plasticizer concentration increases.

How is Corn Starch Plastic Made?

Lactic acid, a colorless transparent liquid produced by modern biotechnology, is extracted from starchy corn kernels. A special polymerization process is used to create polylactic acid, a polymer material. Corn contains three components: starch, protein, and fiber, which must be separated.

The following are the steps involved in the process:

- After harvesting the corn, it is soaked and ground to separate the endosperm from the fiber and gluten. Polymer filaments made from corn starch This is a typical step in the grain crop harvesting process. The corn kernels are immersed in a solution of hot water and sulfur dioxide, which causes the components to degrade into starch, protein, and fiber.

- It is centrifuged to remove the corn oil, leaving almost pure starch behind.

- Enzymes are added to the starchy endosperm, converting it to dextrose, a simple sugar.

- Bacterial cultures are introduced, causing the sugar to ferment and convert to lactic acid. Brewers make beer using the same fermentation process.

- Lactic acid is made up of lactide molecules that bond together to form long polymer chains.

- At the end of the process, bioplastic producers have pellets of polylactic acid plastic. These can be melted into almost any shape or spun into fibers.

Note:

A great demand for green products has led to a growing industry for manufacturing corn starch products. Many countries around the world have banned the use of traditional, petroleum-based plastic bags, so polylactic acid corn starch is poised to play a big role as a viable and biodegradable replacement

Features of Corn Starch tableware

Biodegradable

As a new type of biodegradable material, which is derived from renewable starch resources, such as corn, cassava and other crops. It is fermented and extracted by microorganisms to obtain lactic acid, and then refined, dehydrated, oligomerized, pyrolyzed, and polymerized.

Corn starch products can be completely degraded by microorganisms in the soil within 3 months after being discarded, generating CO2 and water, and no pollution to the environment. Corn Starch raw materials are widely used in the production of packaging materials, disposable tableware, appliance shells, fibers, 3D consumables, etc.

Since Corn Starch is derived from renewable plant resources, rather than petroleum-based traditional plastics, it can truly achieve energy conservation and environmental protection, and is considered the most promising new “ecological material”.

Physical and Mechanical properties

- Microwaven, Fridge and Freezer safe

- Good density, water resistance, oil resistance, anti-soaking

- Density: 1.20-1.30 kg/L

- Melting point: 155-185°C,

- Intrinsic viscosity IV: 0.2-8 dL/g

- Glass transition temperature: 60-65°C,

- Heat transfer coefficient: 0.025 λ(w/m*k)

- Tensile strength: 40-60 MPa

- Elongation at break: 4%-10%

- Modulus of elasticity: 3000-4000 MPa

- Flexural modulus: 100-150 MPa

- Izod impact strength (unnotched): 150-300 J/m

- Izod impact strength (notched): 20-60 J/m

- Rockwell hardness: 88

SPI Logo of the Corn Starch tableware

The Society of Plastics Industry (SPI) stipulates that the digital identification code of corn starch is “7”. Belgium has begun to use recycled polylactic acid as a pilot country. The recycling of corn starch is not the same as other polymers. The waste polylactic acid plastic will be collected in a special container, degraded into small molecule monomers through pyrolysis, hydrolysis and other methods, and then the monomer will be converted by the manufacturer. Lactic acid is synthesized into a polylactic acid raw material with certain properties, which will be used again in the market.

Advantages of Corn Starch Tableware

With so many features, quality products, and such facets, it is easy to conclude that corn starch tableware offers several advantages to users, as detailed below:

- Such tableware is made from corn starch using cutting-edge technology and methods, resulting in efficient and high-quality tableware that is completely eco-friendly in use.

- It is completely safe for human consumption, unlike other petrol-based products that may contain toxins and other harmful components.

- These easily degrade into water and carbon dioxide, resulting in zero pollution, which means no pollution of the air and soil.

- Plastic and paper tableware use a certain amount of petrochemicals and wood, whereas starch-based tableware does not because it is infinite.

- These have water and oil resistance, anti-soaking, anti-osmosis properties, high density, and can withstand low and high temperatures effectively. As a result, they are ideal for various food storage applications.

- Making tableware from corn starch allows you to save other types of resources.

Whatever type of tableware you imagine, corn starch can be used to make it. It can be used to make bowls, cups, and much more.

What Should You Look for When Purchasing Corn Starch Tableware?

When buying corn starch tableware there are certain points that you need to remember and follow like:

Look for a Specialist Manufacturer: When purchasing any type of tableware or other product, it is critical to buy from a brand that specializes in that particular product. A specialist manufacturer employs cutting-edge technology and best practices to create valuable products for customers.

Questions and Answers About Corn Starch Tableware

Why can’t you recycle corn plastic with regular plastic? Although the two plastics appear to be the same, their chemical compositions are not. Logo made of corn starch and plastic that can be composted Bioplastic can contaminate traditional plastic recycling, potentially rendering the salvaged plastic useless.

A landfill is so densely packed that there is no light or oxygen to aid in the breakdown of corn starch polymers.

To avoid complications with corn plastic recycling and composting, many commercial composters will only accept bioplastics from food service operations, rather than ordinary households.

Is corn starch tableware biodegradable? It is edible, biodegradable, and carbon neutral.

How long does it take for corn starch plastic to biodegrade? PLA decomposes into water and carbon dioxide in less than 90 days in a controlled composting environment.

Corn Starch is criticized for relying on industrial farming of large fields of crops, which could be used to grow food crops. Much of the corn used in bioplastics is a variety known as Number 2 Yellow Dent, which is primarily used for animal feed. Corn is also used to make ethanol fuel, putting additional strain on farmland.

Is there a Future for Corn Starch Plastic?

Corn starch, in my opinion, has a bright future. Although the bioplastics market is growing at a rate of around 20% per year, it still accounts for less than 1% of the 200 million tons of plastic produced each year.

The raw materials used to make corn starch polymers are inexpensive and simple to produce, making it an excellent way to reduce one’s carbon footprint. It has many applications and has a lower environmental impact than fossil fuel plastic.

A company can choose environmentally friendly packaging materials with a shift toward sustainability and greener options. With the introduction of corn starch-based materials, businesses and consumers can now use more sustainable plastic alternatives to petroleum-based plastics.