First of all, what is compost? Composting, also known as organic recycling, is the decomposition of organic material under natural conditions over time. But how does compost work? Is it fungi, bacteria, microorganisms, worms, and other organisms that break down organic waste to produce nutrient-rich compost?

What is the method of composting?

Mainly, There are two different kinds of composting methods– home composting and industry commercial composting. Today, we’re going to break down the difference between them and take a look at the benefits of the two composting methods.

Why do they matter?

It is important to understand the difference between these two composting methods. In short, it makes it easier to dispose of packaging responsibly, as well as to identify different types of compost bins when out and about.

Because while almost all organic waste can be composted at home, not all compostable packaging can. Some packages can be easily broken down in a home composting system, while some require a managed environment in a commercial facility.

How can we do composting in our home yard?

Home composting is exactly what you think it is – composting is done at home. While the end result of nutrient-intensive soil foods is similar to that of commercial composting facilities, the main difference is that the process is less regulated in terms of temperature and atmosphere. This means: Not all packaging will break down in a home compost environment.

Industrial composting?

Industrial composting involves sending organic waste to commercial facilities for large-scale composting. This type of composting method differs from home composting and is easier to control and maintain.

Types of Industrial composting?

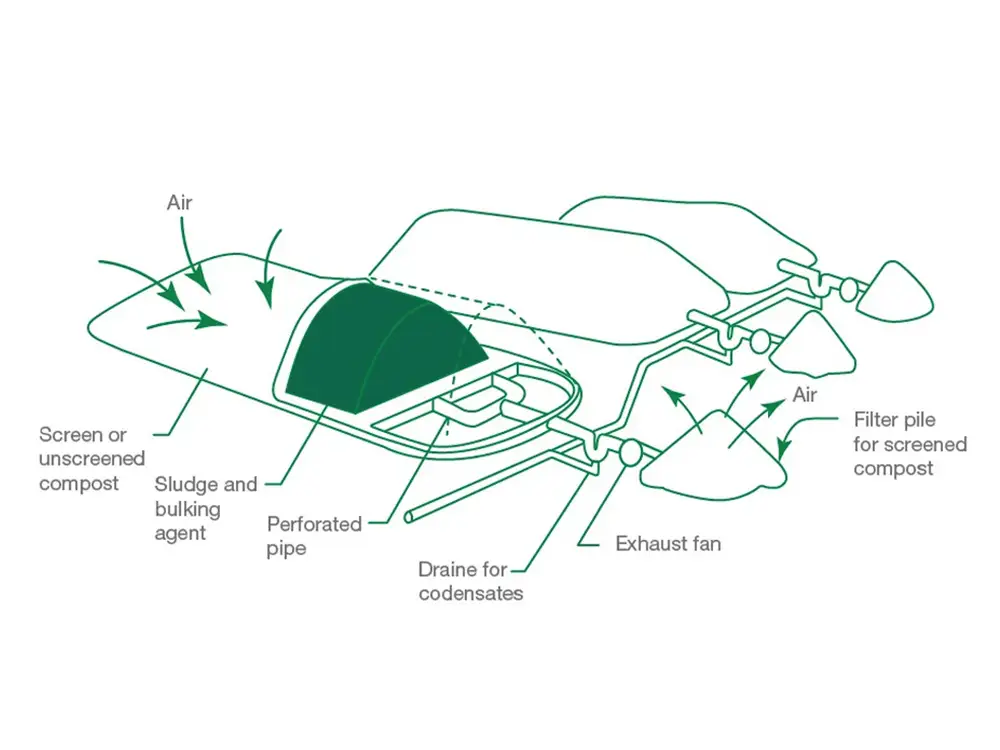

- Aerated Static Pile

The process of stacking decomposed organic materials on an air supply system can be used to supply oxygen and control temperature to produce compost. The piles must be insulated to ensure that all parts of the decomposing material reach and maintain a temperature of 55 degrees Celsius or above for at least three days.

- Turned Windrow

The process of stacking decomposed organic material in long piles to produce compost. The pile is periodically rotated or agitated to ensure the desired stability of all parts of the decomposed material.

- In-vessel

Process in which decomposing organic material is enclosed in a drum, silo, bin, tunnel, or other containers for the purpose of producing compost; and in which temperature, moisture, and air-borne emissions are controlled, vectors are excluded and nuisance and odor generation minimized.

Learn more about the differences between home and commercial composting.

Composting Standards

It’s really important to look out for composting certifications when disposing of compostable packaging. At Get Bio Pak, we adhere to European standards: AS4736 for industry compostable, and AS5810 for home compostable.

For home compostable packaging, look for this symbol.

For commercially compostable packaging, look for this symbol.